Alare

WHY ALARE

Designing an high-end loudspeaker is a mechanical, electrical, and acoustic challenge. If the goal is to maintain untouched harmonic structures and instrumental timbres, Alare products keep this promise to satisfy expectations of most discerning music lovers. Elegantly crafted in Italy and built with finest materials and components, Alare loudspeakers are carefully designed with the purpose of achieving the best performances ever, so owners will enjoy them for many years to come.

WHAT WE DO

To reach best performance ever, we use the most updated technologies available. Latest digital measurement devices, precision microphones, displacement lasers, accelerometers, computer aided design and simulation software packages. Each component is carefully examined, tuned and controlled before shipping. Our quality control is derived from a total control for every step of manufacturing. What defines and makes us who we are is our passion, creativity, ingenuity and a sense of belonging to our country, Italy.

WHY EXOTIC MATERIALS FOR HIGH END DRIVERS?

The woofers: carbon

Woofer cones from Danish Audio Technology are made from two thin carbon reinforced paper cones, which are glued together with an expanding foam, using a support tool, to keep the cone in the correct shape. The foam is well damped to avoid resonances in the cone. The result is an extremely rigid and stiff cone, presenting fast, uncolored and distortion free bass. The voice coil is made from a mixture of kapton and aluminum. This means, the driver acts as a pure kapton voice coil driver, as long as the voice coil is within its linear working area. It also presents a very low mechanical resistance, which allows the driver to play bass with authority, even at low levels. All drivers are naturally generously ventilated, under the spider, from voice coil gap and not least through the pole piece, allowing the whole moving system to travel fast and freely, without any compression.

The midrange: ceramic

In 1984 the Backes & Müller production-engineer Bernhard Thiel invented a process to produce very thin sheets of extremely hard corundum (Al2O3), also known as sapphire. This patented procedure allowed the manufacturing of very stiff, light weighted and highly damped loudspeaker calottes. This new and very hard material facilitates loudspeaker drivers with broader bandwidth, lower distortion and a purer sound than ever before possible. This technology can be found in all our midranges made by German brand Accuton.

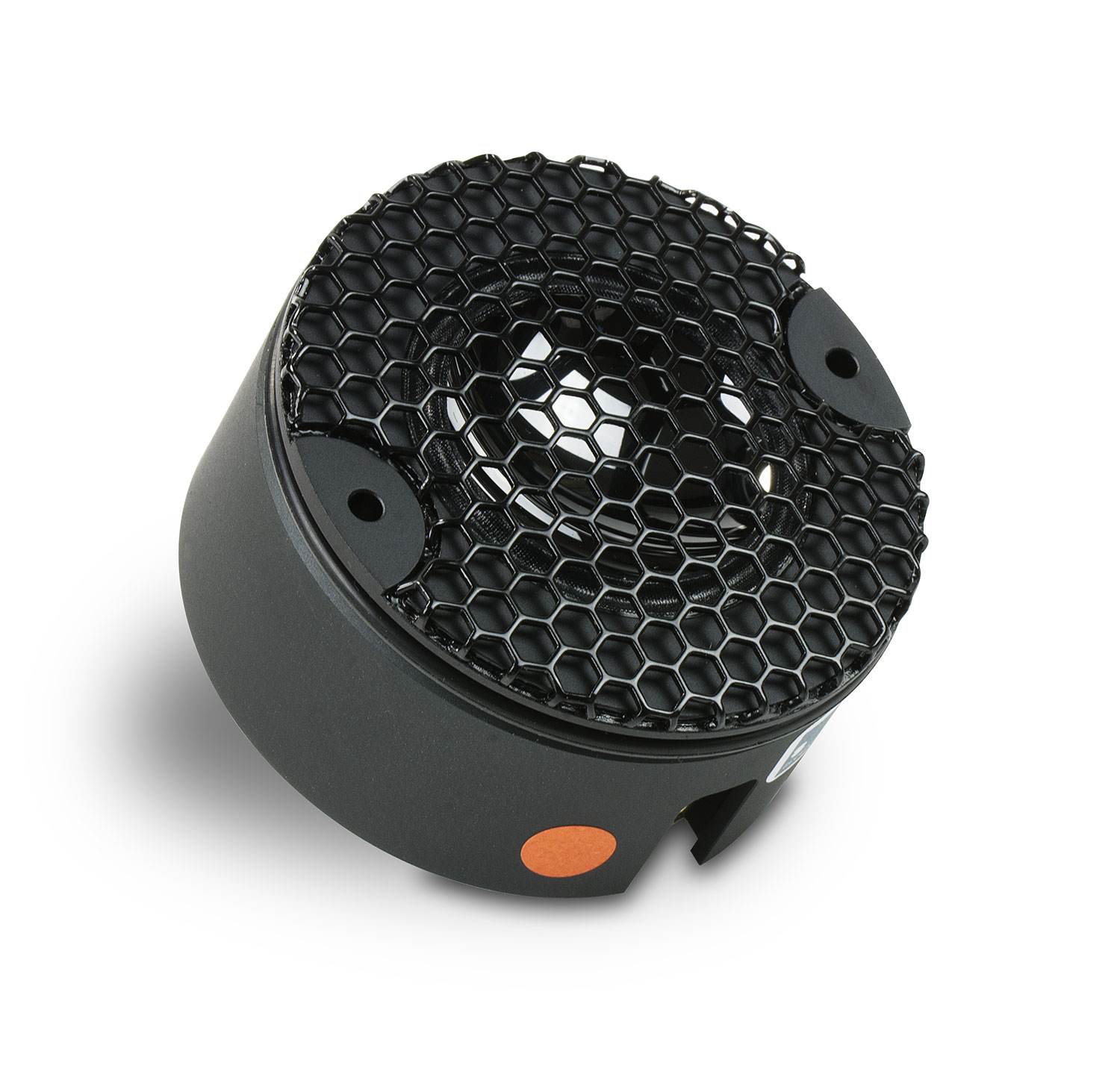

The tweeter: diamond

A thin dome of diamond is ideal for a tweeter because the stiffness to weight ratio of this material is really unsurpassed. A concave dome is used because the moving assembly is more rigid and better damped than convex domes, and it also shows a better dispersion. For this reason, the sonic character of diamond tweeters is not what you could expect, an overly “brilliant” sound, but it is just the opposite. The diamonds simply disappear, only music remains. This is a new way of relaxed listening and once you get used to it, you will never go back to other more conventional technologies.